Gauge Fillet Weld Fundamentals: Best Practices and Common Mistakes

Gauge Fillet Weld Fundamentals: Best Practices and Common Mistakes

Blog Article

Innovative Strategies to Fillet Weld Evaluation and Screening: Enhancing Weld High Quality and Conformity Requirements

In the world of welding, the high quality and integrity of fillet welds play a vital duty in making certain the structural sturdiness and dependability of numerous industrial parts. With the continuous drive for improved effectiveness and conformity with rigorous criteria, the exploration of innovative techniques to fillet weld evaluation and testing has actually become essential. As sectors progress, the traditional approaches may no much longer be sufficient in meeting the needs of contemporary welding applications (Gauge Fillet Weld). By embracing sophisticated modern technologies and methodologies, a new horizon of possibilities emerges in the realm of weld high quality evaluation and adherence to compliance criteria.

Advanced Non-Destructive Screening Approaches

Utilizing state-of-the-art modern technologies, progressed non-destructive screening approaches play a critical duty in making certain the honesty and quality of fillet welds. These approaches, such as phased range ultrasonic testing (PAUT) and magnetic fragment screening (MPT), deal in-depth insights right into the weld's inner structure without creating any type of damages to the material. PAUT, for example, uses multiple ultrasonic elements to check the weld from numerous angles, offering a comprehensive visualization of possible defects like lack of blend or splits.

By employing these sophisticated non-destructive screening strategies, weld assessors can precisely analyze the quality of fillet welds, making certain compliance with market criteria and laws. The capability to discover imperfections early on not just enhances weld top quality yet likewise protects against pricey rework or failures in structural honesty, underlining the value of these cutting-edge testing methods in welding assessments.

Robotics and Automation in Inspection

The assimilation of robotics and automation has actually revolutionized the examination process for fillet welds, boosting efficiency and precision in top quality assessment. Robotics offer precise control and repeatability in examining welds, making certain constant and dependable outcomes. Automated systems can be configured to comply with specific assessment courses, making sure detailed protection of welds and lowering the danger of human error.

Robot inspection systems furnished with advanced sensors can identify and determine weld attributes with high accuracy, offering comprehensive information for analysis. These systems can determine flaws such as fractures, lack of fusion, and porosity, making it possible for timely restorative activities to be taken. In addition, robotics and automation enable real-time data collection and evaluation, supplying prompt feedback to drivers and helping with quick decision-making procedures.

Furthermore, the use of robotics and automation in fillet weld examination improves total productivity by decreasing evaluation times and raising examination throughput. By streamlining the evaluation process, suppliers can make certain weld high quality and conformity standards are met effectively, inevitably bring about cost financial savings and enhanced product top quality.

Using Artificial Knowledge for Evaluation

Artificial knowledge plays a crucial function in enhancing the performance and precision of analysis in fillet weld examination processes. AI algorithms can swiftly refine substantial amounts of data from weld assessments, discovering issues or variances that may be testing to determine with the nude eye.

Moreover, AI systems can pick up from previous examination data, continually boosting their ability to recognize prospective problems and deviations in fillet welds. This flexible discovering ability improves the general high quality control process, decreasing the likelihood of human error and making sure that useful reference welds meet the called for criteria. By incorporating fabricated intelligence right into fillet weld analysis, industries can accomplish greater degrees of effectiveness, uniformity, and compliance in their inspection practices.

Portable Equipment for On-Site Examination

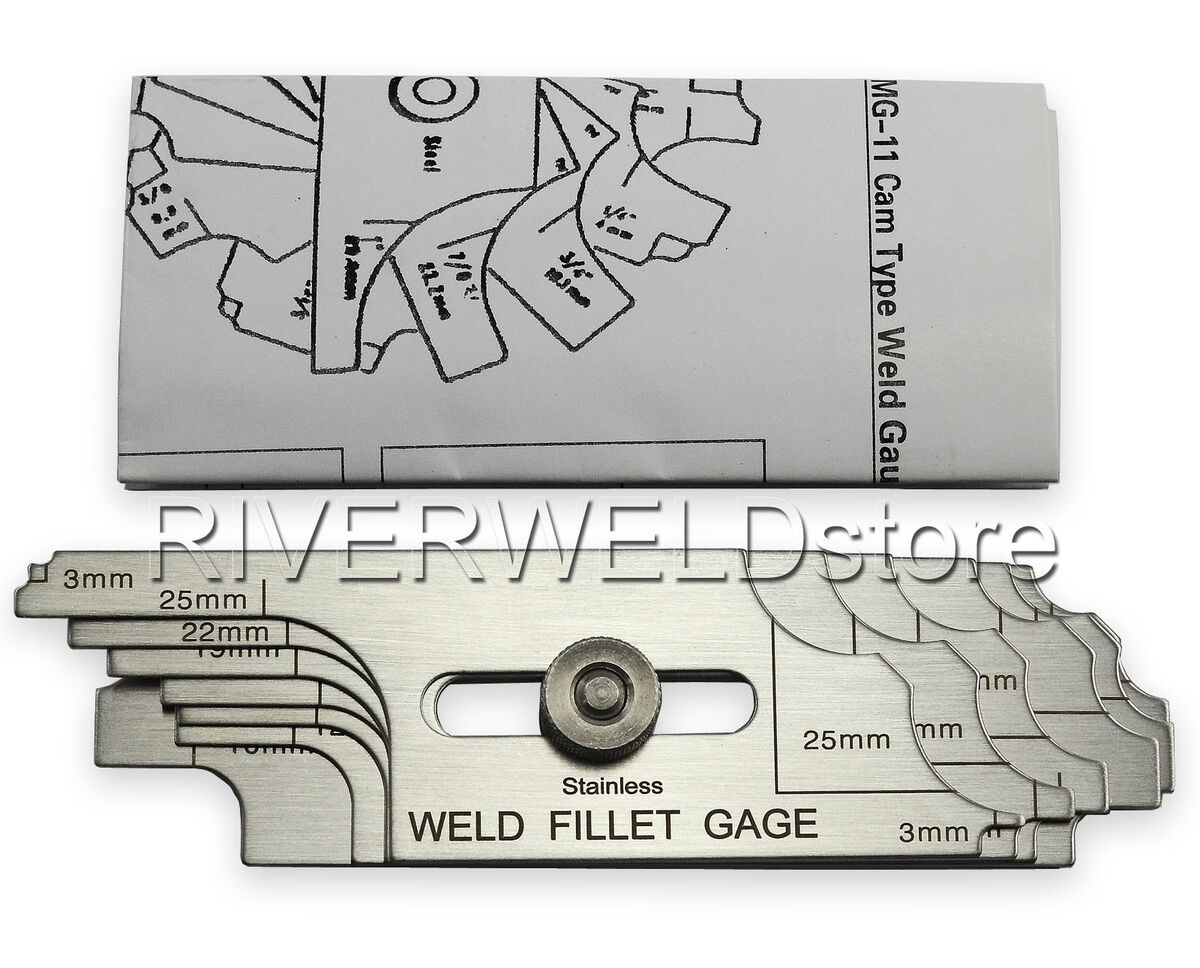

Enhancing area evaluation effectiveness, the adoption of portable devices revolutionizes on-site assessment processes for fillet welds. These tools use versatility and comfort, allowing examiners to carry out extensive evaluations in numerous locations, including remote or visit tough environments. Portable devices such as ultrasonic screening tools, magnetic particle examination devices, and electronic radiography systems supply real-time information and high-resolution imaging abilities, enabling quick decision-making and prompt comments on weld quality.

One considerable advantage of portable devices is their capability to streamline assessment procedures, lowering downtime and improving general efficiency - Gauge Fillet Weld. Inspectors can quickly carry these devices to various job sites, removing the demand for transferring hefty equipment or components to off-site facilities. Additionally, the portability of these tools advertises cost-effectiveness by lessening transport costs and accelerating inspection timelines

Furthermore, making use of mobile devices for on-site evaluation advertises proactive top quality control measures, as inspectors can immediately identify and resolve any potential welding defects or inconsistencies. By integrating these cutting-edge modern technologies into on-site assessment methods, welding experts can make certain conformity with industry requirements and enhance weld top quality, inevitably resulting in improved structural stability and safety and security in different welding applications.

Assimilation of Data Management Systems

Having actually maximized on-site examination procedures via the application of portable tools, the following phase involves the seamless assimilation of data administration systems to even more improve efficiency and information analysis abilities in fillet weld inspection and testing. By integrating information administration systems into the evaluation process, organizations can streamline information collection, storage space, and evaluation. This combination enables for real-time surveillance of weld top quality, immediate identification of problems, and timely decision-making to correct any concerns that might emerge during the assessment process.

The combination of data management systems enables seamless communication between various stakeholders entailed in the examination procedure, fostering cooperation and boosting overall high quality control procedures. Eventually, the combination of information management systems offers to raise the criteria of fillet weld assessment and screening, making sure conformity with industry regulations and improving weld top quality.

Verdict

Finally, ingenious strategies to fillet weld inspection and testing have considerably enhanced weld top quality and conformity criteria. Advanced non-destructive testing techniques, robotics, automation, expert system, portable tools, and data management systems have revolutionized the means weld inspections are performed. By making use of these technologies, industries can guarantee that welds fulfill the needed high quality standards and policies, ultimately enhancing overall performance and safety in welding processes.

Having maximized on-site examination procedures via the usage of portable tools, the following phase includes the seamless assimilation of data management systems to even more boost efficiency and information evaluation capabilities in fillet weld inspection and screening. Inevitably, the integration of information monitoring systems offers to boost the criteria of fillet weld examination and testing, making certain compliance with industry guidelines and improving This Site weld quality.

Report this page